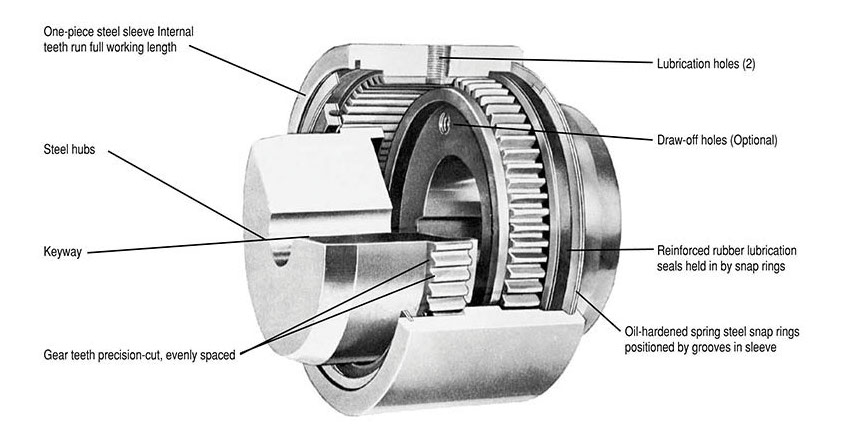

Gear couplings are critical components in power transmission systems, especially when handling high torque and heavy loads. Designed to connect two shafts at their ends, gear couplings transmit torque efficiently between non-coaxial shafts. They consist of two hubs with external teeth connected by a sleeve or third shaft (spindle), allowing for minimal backlash and accommodating slight misalignment.

Why Choosing the Right Gear Coupling Matters for Performance and Longevity

“To properly select a gear coupling, several key factors need to be considered, including the application, power requirements, misalignment, and available space.”

At UNI-Drive Technologies, we emphasize the importance of selecting the right gear coupling, as it directly affects system performance, durability, and operational safety. Well-designed and properly maintained gear couplings not only reduce wear and tear on connected components but also enhance equipment lifespan and efficiency.

Key Benefits of Quality Gear Couplings:

✅ High torque capacity for demanding applications

✅ Compact and space-saving design

✅ Excellent torsional rigidity

✅ Can handle moderate axial movement shaft while maintaining torque transmission

✅ Reliable under harsh conditions – high temperature surrounding

✅ Suitable for high RPM, meeting AGMA, ISO and DIN balancing standards

✅ Various shaft attachment designs for versatility in installations

✅ Good for reverse rotation and bidirectional use

Whether you’re dealing with misalignment, high loads, or critical speed demands, selecting the right gear coupling is essential for preventing breakdowns and optimizing system performance.

Factors to Consider for Long-Term Reliability:

Maintenance is the final factor to ensure gear coupling reliability for long equipment life. :

Lubrication: Proper lubrication is crucial for the longevity of gear couplings. Use the recommended grease or oil based on temperature and application. Poor lubrication between the gear teeth generates higher friction between these teeth, resulting in gear coupling wear, heat generation and high axial loads to mating equipment bearings.

Installation: Proper installation and alignment are essential for preventing premature wear and failure.

Maintenance: Perhaps the most important operating factor for a gear coupling to be reliable is regular inspections and maintenance, including lubrication and checking for wear. Typical recommendations are regreasing at a minimum of 12 months. A regreasing procedure would include breaking, cleaning, inspecting and hand-packing the coupling with fresh grease.

Why Choose UNI-Drive?

With over 30 years of experience in the mechanical power transmission industry, UNI-Drive Technologies offers a comprehensive range of coupling solutions tailored to your operational needs. Our product line includes:

-

Gear Couplings

-

Flexible Couplings

-

Rigid Couplings

-

Grid Couplings

-

Chain & Tyre Couplings

We also provide custom-engineered solutions to meet unique specifications and industry requirements. Reach out to our technical team today to find the right solutions for your application — and experience the UNI-Drive advantage in performance, reliability, and service.

Explore our range of mechanical and industrial solutions or reach out to our team for expert advice today!

—

—